Details of Completed Key Projects

Scope of Work:

EPC Contract for Construction of Mounded Type 1650 MT X 15 Nos Tanks, Total 30,000 MT LPG Import Terminal Largest Mounded LPG Bullet Based Terminal in the World

| Design code | ASME Sec VIII Div 2 |

| Design Pressure | 17.24 Bar at the Top |

| Capacity each of Bullet | 3450 Cu M |

| Thickness of Shell | 38 mm |

| Diameter of Sphere | 8.0 meter Diameter x 68 meter Length |

Scope of Work:

EPC Contract for Construction of Mounded Type 1000 MT X 2 Nos Tanks, Total 2000 MT LPG Import Terminal 70mm X 3m Wide Rolling Machine installed

| Design code | ASME Sec VIII Div 2 |

| Design Pressure | 17.24 Bar at the Top |

| Capacity each of Bullet | 2100 Cu M |

| Thickness of Shell | 46 mm |

| Diameter of Sphere | 10.0 meter Diameter x 34 meter Length |

Scope of Work:

Construction Of 3000 MT LPG Import Terminal With Jetty Piping

| Design code | ASME Sec VIII Div 2 |

| Design Pressure | 14.5 Bar at the Top |

| Capacity each of Sphere | 3000 Cu M |

| Thickness of Shell | 38 mm |

| Diameter of Sphere | 18 m |

| Ship Unloading Rate | 200MT/ Hr |

Scope of Work:

Construction of 2500 MT LPG Import Terminal with Jetty Piping

| Design code | ASME Sec VIII Div 2 |

| Design Pressure | 14.5 Bar at the Top |

| Capacity each of Bullet | 5000 Cu M |

| Thickness of Shell | 40 mm |

| Diameter of Sphere | 22 m |

| Ship Unloading Rate | 250 MT/ Hr |

Scope of Work:

A) Decommissioning of Refrigerated Storage Tanks. B) Cleaning of Refrigerated Storage Tanks on decommissioning along with suitable for exhaustive NDT inspection & other works.

| Storage capacity per tank | 15000 MT |

| Design code | API 620 Appendix R / 1990 |

| Inside diameter of Inner Shell | 45200 mm |

| Inside diameter of Outer Shell | 46800 mm |

| Height of Inner Shell | 18400 mm |

| Height of Outer Shell | 20000 mm |

Scope of Work:

EPC Contract for Construction of 20 meter Diameter LPG rated Sphere with Storage Capacity of 2000MT. Along with 200 meters of 6 inch Aboveground Jetty Piping with Ship Unloading Facility Details of Sphere as follows:-

| Design code | ASME Sec VIII Div 2 |

| Design Pressure | 14.5 Bar at the Top |

| Capacity each Sphere | 3840 Cu M |

| Thickness of Shell | 42mm |

| Diameter of Sphere | 20m |

| Ship Unloading Rate | 200MT/ Hr |

Scope of Work:

EPC Contract for Construction of 2 Nos1054 cu m, On site fabrication of LPG rated Mounded Type Bullets with Storage Capacity of 1000MT, with 400MT Per day Road Tanker Loading facility

| Design code | ASME Sec VIII Div 2 |

| Design Pressure | 14.5 Bar at the Top |

| Capacity each Sphere | 1054 Cu M |

| Thickness of Shell | 28mm |

| Diameter of Sphere | 6.3 meter Diameter x 35 meter Length |

| Ship Unloading Rate | 200MT/ Hr |

Scope of Work:

EPC Contract for Mechanical Piping and Filling Shed with 2 x 24 Head Carousel. Bottling plant Configuration:-

| Storage Capacity | 600 MT X 3 Nos LPG Bullets , Mounded Type |

| Filling Shed | 24 Head Carousel x 2 Nos Supplied by M/s Kosan Crisplant |

| Tanker loading shed | 8 Nos Tanker Loading, Unloading shed with latest equipment in Place |

Scope of Work:

EPC Contract for Mechanical Piping and Filling Shed with 2 x 24 Head Carousel. Bottling plant Configuration:-

| Storage Capacity | 600 MT X 3 Nos LPG Bullets , Mounded Type |

| Filling Shed | 24 Head Carousel x 2 Nos Supplied by M/s Kosan Crisplant |

| Tanker loading shed | 8 Nos Tanker Loading, Unloading shed with latest equipment in Place |

Scope of Work:

EPC Contract for Construction of 5 Nos x 350 cu m, On site fabrication of LPG rated Aboveground Type Bullets with Storage Capacity of 750MT, with 200MT Per day Road Tanker Loading facility

| Design code | ASME Sec VIII Div 2 |

| Design Pressure | 14.5 Bar at the Top |

| Capacity each Sphere | 350 Cu M |

| Thickness of Shell | 22mm |

| Diameter of Sphere | 4.3 meter Diameter x 25 meter Length |

| Ship Unloading Rate | 100MT/ Hr |

Scope of Work:

EPC Contract for 1000MT LPG Rated Mounded Type Installation. Along with 24 head Carousel and Complete Bottling plant.

| Design code | ASME Sec VIII Div 2 |

| Design Pressure | 14.5 Bar at the Top |

| Capacity each Sphere | 1054 Cu M |

| Thickness of Shell | 28mm |

| Diameter of Sphere | 6.3 meter Diameter x 35 meter Length |

| Filling Shed | 24 Head Carousel of SIRAGA Make, All Filing Shed Equipment, Valve replacement without the cylinder evacuation. |

Scope of Work:

EPC Contract for Construction of 22 meter Diameter LPG rated Sphere with Storage Capacity of 2500MT. Along with 10 inch x 2000 Meter Aboveground Jetty Piping with Ship Unloading Facility. Details of Sphere as follows:-

| Design code | ASME Sec VIII Div 2 |

| Design Pressure | 14.5 Bar at the Top |

| Capacity each Sphere | 5000 Cu M |

| Thickness of Shell | 40mm |

| Diameter of Sphere | 22m |

| Ship Unloading Rate | 250MT/ Hr |

Scope of Work:

EPC Contract for Construction of 150MT Each x 2 Nos LPG rated Mounded Type Installation along with Civil, Electricals, instrumentation, NACE IV Certified Cathodic Protection system. Details of Sphere as follows:-

| Design code | ASME Sec VIII Div 1 |

| Design Pressure | 14.5 Bar at the Top |

| Capacity each Sphere | 380 Cu M |

| Thickness of Shell | 32mm |

| Size of Bullet | 4.0 meter Diameter x 25 meter Length |

Scope of Work:

EPC Contract for Construction of 150MT Each x 3 Nos LPG rated Mounded Type Installation along with Civil, Electricals, instrumentation, NACE IV Certified Cathodic Protection system. Details of Sphere as follows:-

| Design code | ASME Sec VIII Div 1 |

| Design Pressure | 14.5 Bar at the Top |

| Capacity each Sphere | 380 Cu M |

| Thickness of Shell | 32mm |

| Size of Bullet | 4.0 meter Diameter x 25 meter Length |

Scope of Work:

EPC Contract for Construction of 150MT Each x 3 Nos LPG rated Mounded Type Installation along with Civil Designs, Electricals, instrumentation, NACE IV Certified Cathodic Protection system, Automation, 4000 Kg/Hr LPG vaporisers. Details of Bullets as follows:-

| Design code | IS 2825 |

| Type | Mounded Type |

| Design Pressure | 21 Bar at the Top |

| Capacity each of Bullet | 350 Cu M |

| Thickness of Shell | 28mm |

| Size of Bullet | 4.0 meter Diameter x 20 meter Length |

| Road tanker unloading capacity | 2 Nos at a time |

| LPG Vaporisation Capacity | 4000 Kh/Hr |

Scope of Work:

EPC Contract for Construction of 100MT Each x 4 Nos LPG rated Aboveground Type Installation along with Civil Designs, Electricals, Instrumentation, Automation, 4000 Kg/Hr LPG vaporisers. Details of Bullets as follows:-

| Design code | IS 2825 |

| Type | Mounded Type |

| Design Pressure | 21 Bar at the Top |

| Capacity each of Bullet | 350 Cu M |

| Thickness of Shell | 28mm |

| Size of Bullet | 4.0 meter Diameter x 20 meter Length |

| Road tanker unloading capacity | 2 Nos at a time |

| LPG Vaporisation Capacity | 4000 Kh/Hr |

Scope of Work:

EPC Contract for Construction of 150MT Each x 2 Nos LPG rated Aboveground Type Installation along with Civil Designs, Electricals, Instrumentation, NACE IV Certified Cathodic Protection system, Automation, 4500 Kg/Hr LPG vaporisers. Details of Bullets as follows:-

| Design code | IS 2825 |

| Type | Mounded Type |

| Design Pressure | 21 Bar at the Top |

| Capacity each of Bullet | 350 Cu M |

| Thickness of Shell | 28mm |

| Size of Bullet | 4.0 meter Diameter c 30 meter Length |

| Road tanker unloading capacity | 2 Nos at a time |

| LPG Vaporisation Capacity | 4500 Kh/Hr |

Scope of Work:

LNG Installations For Industries Details of LNG Installations as follows:-

| Design code | EN 13458 Annex C |

| Capacity each of Tank | 106 Cu M |

| Type | Double Wall, Cryogenic |

| Design Pressure | 6 Bar |

| Thickness of Shell | 8mm Inner/ 10mm Outer |

| Size of Tank | 4 meter Diameter x 24 meter Height |

Scope of Work:

EPC Contract for Revamping of 10,000 CU M External Floating Roof Storage Tank along with associated Civil Works Details of Tank are as follows:-

| Design code | API 650 |

| Type | External Floating Roof Tank |

| Capacity each of Tank | 10,000 Cu M |

| Thickness of Shell | 10/12 mm |

| Size of Tank | 34 meter Diameter x 12 meter Height. |

Scope of Work:

EPC Contract for Turnaround Jobs for 6 Nos x 3000 CU M LPG and Propane Rated Spheres includes complete replacement of MVWS, NDT, Hydro Testing, Painting work. Details of Sphere are as follows:-

| Design code | PD 5500 |

| Type | Sperical tank |

| Capacity each of Sphere | 3000 Cu M |

| Design Pressure | 14.5 Bar for LPG rated and 21 Bar for Propane Rated Spheres |

| Thickness of Shell | 38 mm |

| Size of Sphere | 18 meter Diameter |

Scope of Work:

We have executed various configurations of Auto LPG Station in India and Other Countries. Our Auto LPG Stations come with Underground Storage Tanks or Skid Mounted Storage Tanks, Aboveground Pumps or Submersible Pumps, Latest in Technology Fore Court Automation with Remote Connectivity

Standard Configurations of the Auto LPG Stations are as follows:-

1. 10 KL x 1 Nos Autogas Tank Mounded on the Skid with One Dual Hose LPG Dispenser

2. 10 KL x 1 Nos Autogas Underground Tank with One Dual Hose LPG Dispenser

3. 10 KL x 2 Nos Autogas Underground Tank with One Dual Hose LPG Dispenser

4. 20 KL x 1 Nos Autogas Underground Tank with One Dual Hose LPG Dispenser

5. 20 KL x 2 Nos Autogas Underground Tank with Two Dual Hose LPG Dispenser

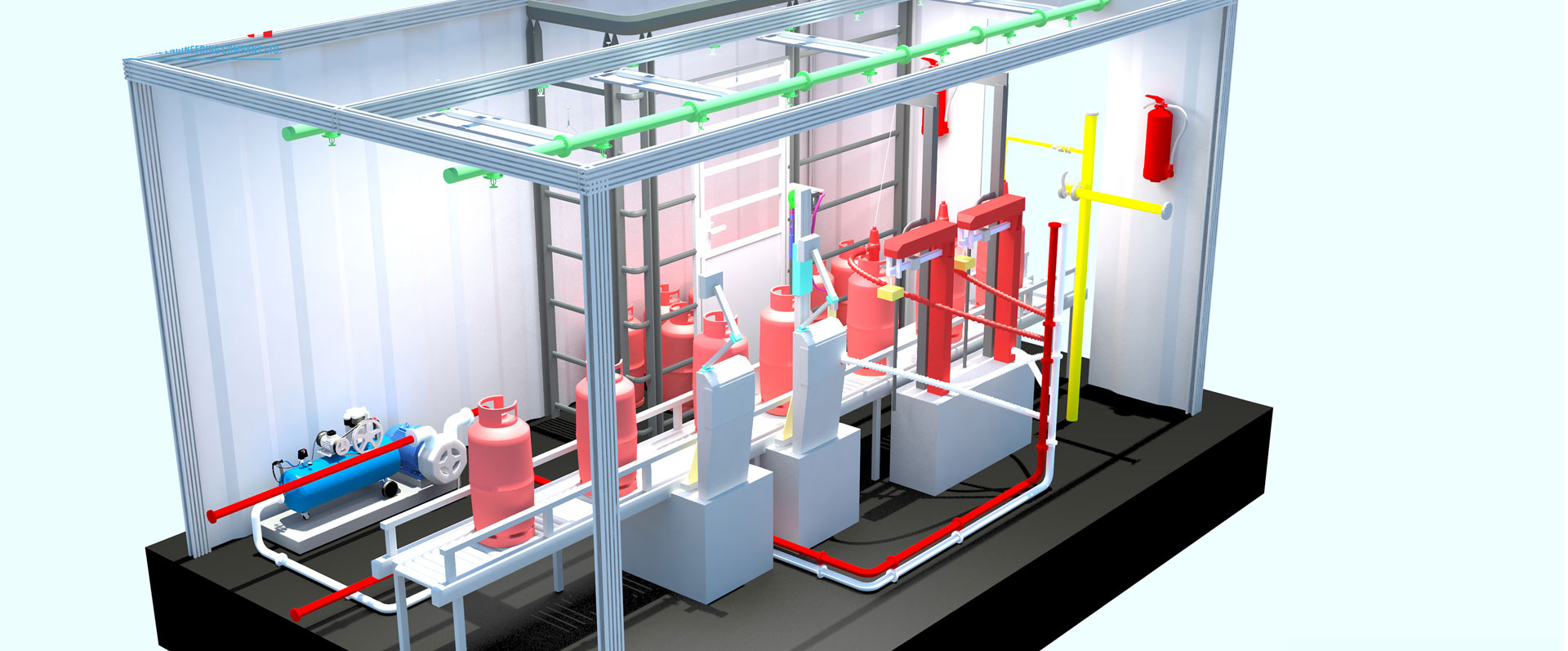

Scope of Work:

We provide Ultra Compact and Mobile LPG Cylinder Filling Plants mounted in a 20 Ft or 40 Ft Container with all the necessary LPG Cylinder Filing Machineries in place. These are equipped with Various Unit Operations like

1. Purging System

2. Manual or Electronic Filling System

3. Check Scales

4. Leak detection system

5. Roller Conveyor system

6. Fire Fighting system

7. LPG Pump

8. Air Compressor unit

And Many More

Scope of Work:

We provide SKID Mounted Ultra Compact and Mobile LPG Cylinder Filling Plants mounted in a 40 Ft Container with all the LPG Filling Machines

1. Excellent tools for seeding new markets

2. Can fill 400 to 800 cycle per day

3. Very versatile and rugged design for long

4. Maintenance free working

Scope of Work:

LPG And Ammonia Special Use Vaporiser System For Requirements Which Are Not Normal

1. Very Very High Capacity Such As 10 MT Per Hr

2. Very Very High Pressure Such As 20 Bar For LPG

3. Fully Automatic Skid Mounted

4. Atmospheric / Solar / Condensate / Waste Heat Recovery Based Vaporisers

Scope of Work:

Many Industries having Natural Gas combustion system cannot use LPG directly unless Burners and Other Control systems are modifies. Sometimes this conversion is very costly and technically unviable too. Under such circumstances we provide a system of Conversion the LPG to Synthetic Natural Gas which has similar combustion properties as that of Natural Gas. These SNG system operate seamlessly with Grid Based Natural Gas supply and LPG Storage Installation giving highest return on Investment for the Consumer

Our Esteemed Clients in this Segment are:-

1. Volkswagen India, Pune, India

2. Mahindra Automotive, Pune, India

3. Shabab textile, Bangladesh

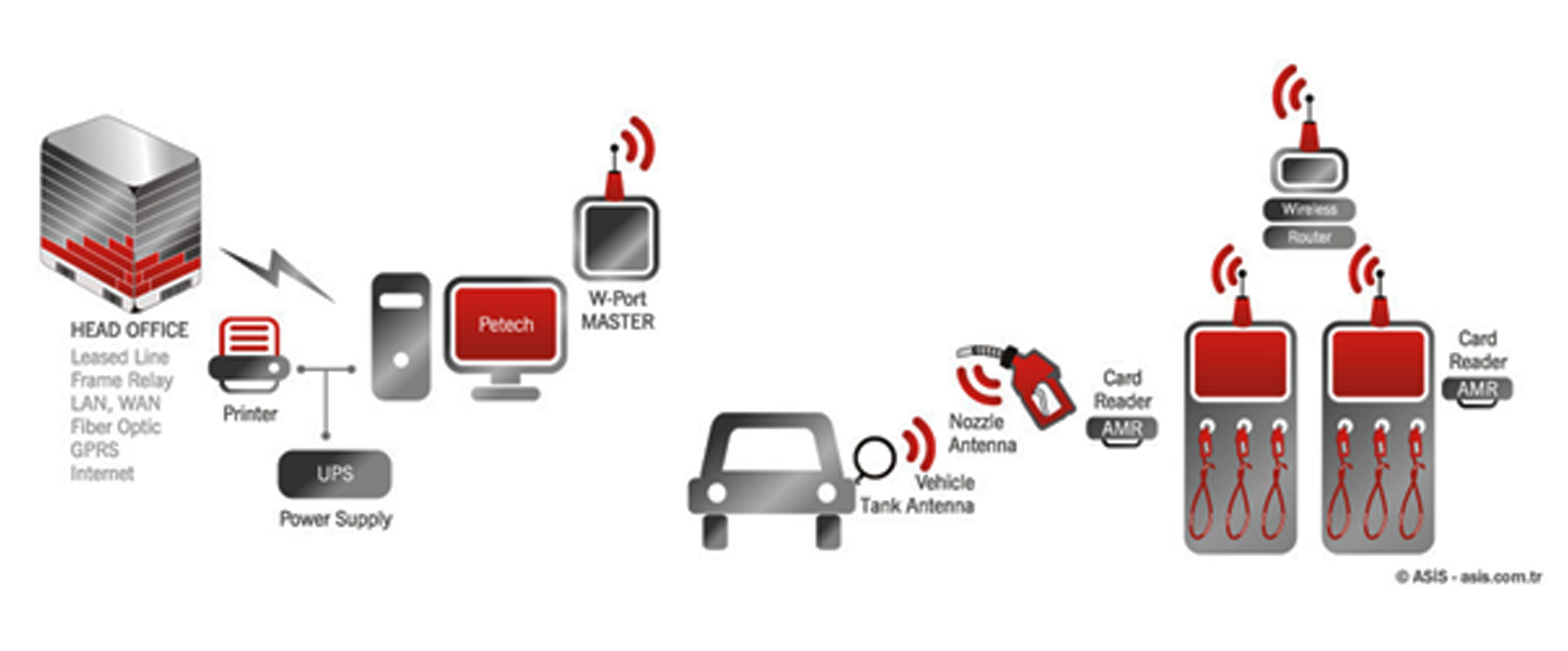

Scope of Work:

Cylinder Banks + Small Tanks + Bulk Installation

1. Remote Metering

2. Prepaid Metering

3. Data Consolidation

Scope of Work:

Car Makers manufacture various varieties of Car on the Single Assembly line with Various Fuel filling requirements for various types of Models. We provide fully Error Proofed systems for Fuel Dispensing with Zero Error Fuel filling in terms of Quality and Quantity. The system also generated MIS reports which are tamper proof and accurate. The system also connects the seamless control for Storage Tanks.

Scope of Work:

Ship Unloading Piping - PIC Receiving Facility, Connection to CBM Jetty and Other Facilities Details of are as follows:-

| Size | 12 inch |

| ONSHORE | 4000 Meter |

| OFFSHORE | 1500 Meter |

Scope of Work:

Construction of Sulphur Melting Furnace as per the Canadian Standards Details of Sulfur Furnace Tank as follows:-

| Length | 45.39 FT |

| Weight | 15.00 FT |

| Height | 14.50 FT |

Scope of Work:

Optech's addition to international clients for Hydrogen Systems Hydrogen tanks with 0.0000% leakage. Duly tested with "Helium leak detection tests"

Scope of Work:

Road Tanker Loading / Unloading System Batch Controller SKID

Scope of Work:

LPG Road Tanker with LPG Delivery System

| Design code | ASME SEC VIII Div.2 Class 2 ED.2023 |

| Design Pressure | 15.8 Bar at the Top |

| No. of Axles & Kerb Weight | 02 & 3000 KG |

| King Pin Size (Dia. MM) | 50 mm |

| Load Bearing Capacity (KN) Semi Trailer | 116 KN |