Optech Engineering Services

Optech Engineering is committed in delivering high quality products and innovative technology to its customers.

In order to give end to end solution company has four main wings.

OPFAB: The Fabrication Shop

Our ISO 9001-2008 certified Pressure Vessel Fabrication Facility at Murbad, Thane Dist, (India) is a state of the art facility with most modern equipments to handle a job of 10 meters height and 40 meters in length and 20 meters in width.

-

Total Area of 3000 SqM

-

15MT Demag OT Crane in Bay 1 + 30MT EOT Crane in Bay 2

-

Plate rolling Machine for 60mm x 3m wide plate – 3 Nos

-

Trolley Mounted Column and Boom Welding Machine with Rotators

-

All In-house NDT facilities

We have decades experience in Designing vessels as per the ASME, PD5500, IS 2825, AD MERKBLATT standards and Our Process is certified by LRIS, BVIS, DNV, TUV, PDIL, Mec Elec and many reputed firms.

Our Products include:

-

LPG / Propane Storage Tanks

-

Ammonia Storage Vessels

-

CO2, H2, N2 and other Industrial Gas Pressure Vessel

-

Large Capacity Vaporisers and Heat Exchangers

-

Speciality Structures and Process Skids

-

Stainless Steel Storage Tanks and Vessels

-

Containerised Bottling Plants

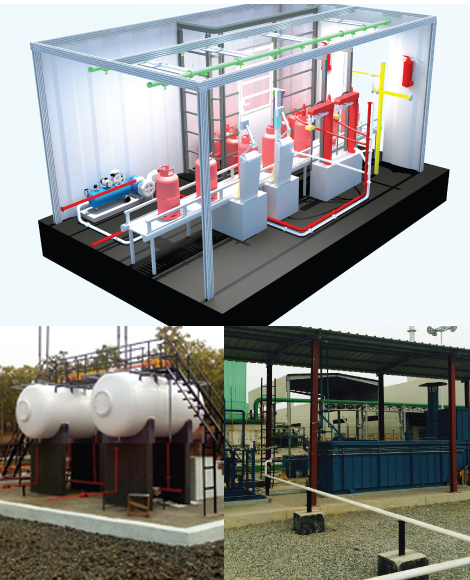

OPCON: Projects and Construction Division

With over a two decades of experience of promoters in the large scale projects, Customers are assured of innovative and reliable designs, well coordinated project execution, Fast and quality Construction in all projects.

Over 700 projects to its credit in India and abroad makes Optech a Reliable Company to choose for your projects.

Our ISO Certified Design, Procurement and Execution process assures lower costs and better quality for our customers.

Our Core Expertise is mainly in the following areas:

-

PROPANE /LPG Storage and Handling Import Terminals and Bulk Storage Facilities with Indigenious & Imported Equipments

-

LNG Storage Terminals for small Industries

-

Large Crude Oil Terminals and Floating Roof Storage Tanks

-

Auto LPG Dispensing Station Skid Mounted and Elaborate

-

LPG Bottling Plants

-

Large Diameter and Specialty Process / Utility Piping

-

All Types of Industrial Hydrocarbon and Chemical Storage Facilities

-

Innovative Instrumentation and Control Systems

OPSERV: 24x7 Onsite Services

An innovative “Business Process Outsourcing” for Large manufacturing companies to save costs and improve safety at your hydrocarbon storage and handling facilities.

Optech offers a dedicated well trained team to operate and maintain your Hydrocarbon storage and handling facilities on 24x7 basis.

What we offer:

-

Regularly Trained technical manpower for round the clock operation of facilities

-

Maintenance schedules prepared and followed meticulously

-

All statutory compliances taken care

-

Spares planning

-

Safety Drills and Regular Improvements with KAIZEN

-

Backed by large OEMs and Service Providers for any Break down

OPTEST: Non Destructive Testing and Certifications

In our best endeavor to become a complete solutions company, Optech has its fourth division which undertakes all the “Non Destructive Testing Procedures and Statutory Certifications” for Hydrocarbon storage and handling facilities.

-

Auto LPG Stations and underground storage tanks

-

LPG/Propane Bulk terminals

-

Radiographic Inspection (ASME Sec VIII Div 1 and Sec IX)

-

Wet Fluorescent Magnetic Particle Inspection (ASTM-A-709 / T-700)

-

Hardness Test (ASTM-E-110-89)

-

Dye Penetration Test (ASTM-E-165-89)

-

Ultrasonic Flaw Detection Test (ASME Sec VIII Div 1 App12)

-

Ultrasonic Thickness Measurement (ASTM-A-4535-89)

-

Hydro Testing (ASME Sec VIII Div 1/2)